Test item 测试名称: Mechanically operated locks, latches and locking plates 锁具要求

Test info 测试内容:

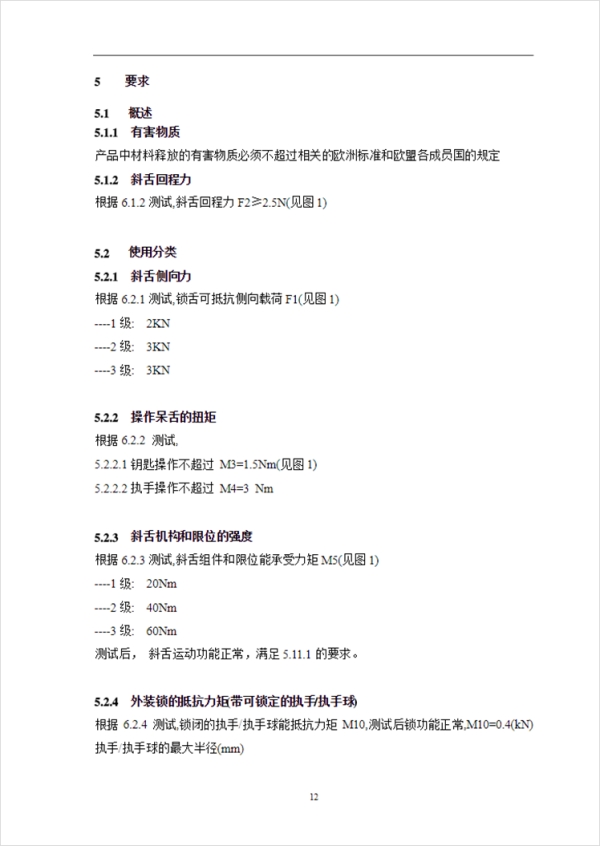

| 5.1 General |

| 5.1.1 Dangerous substances |

| 5.1.2 Return force of latch bolt |

| 5.2 Category of use |

| 5.2.1 Resistance to side load on latch bolt |

| 5.2.2 Torque to operate deadbolt |

| 5.2.3 Strength of normal latch action and stops |

| 5.2.4 Torque resistance of rim lock with lockable handle/knob |

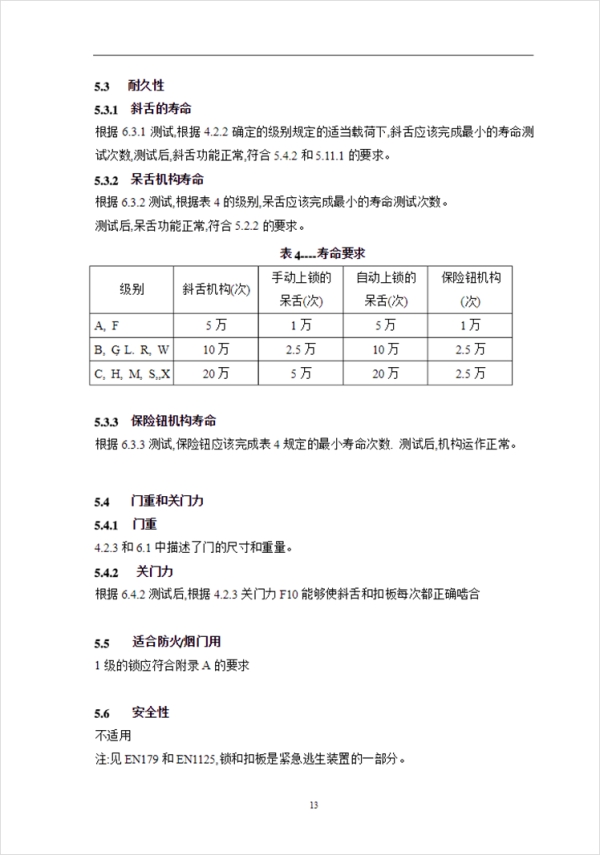

| 5.3 Durability |

| 5.3.1 Durability of latch action, ( 50000 cycles, 10000 cycles, 200000 cycles ) |

| 5.3.2 Durability of deadbolt mechanism ( 10000 cycles, 25000 cycles, 500000 cycles ) |

| 5.3.3 Durability of locking snib mechanism |

| 5.4 Door mass and closing force |

| 5.5 Suitability for use on fire/smoke doors |

| 5.7 Corrosion resistance and temperature |

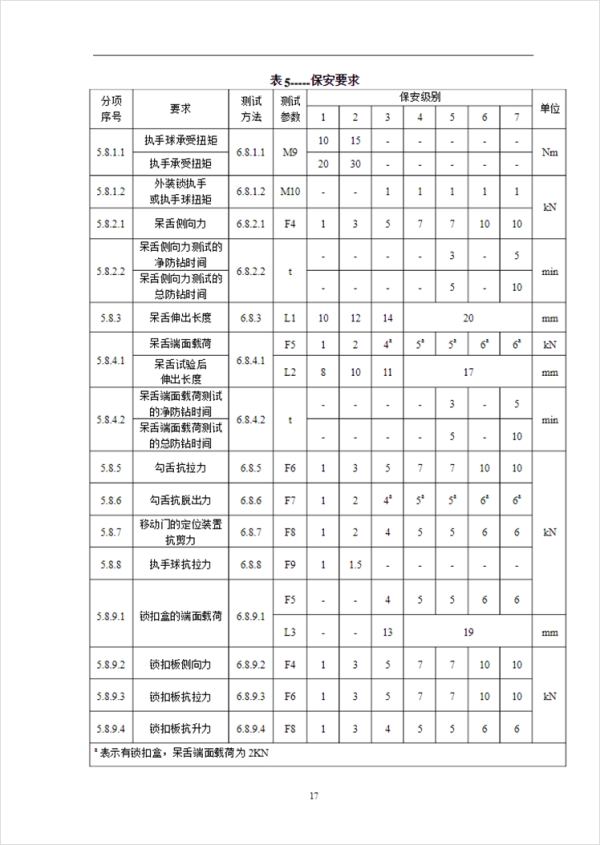

| 5.8 Security |

| 5.8.1 Torque resistance of knob |

| 5.8.2 Resistance to side load |

| 5.8.3 Deadbolt projection |

| 5.8.4 Resistance to end load on deadbolt |

| 5.8.5 Resistance to pulling of hook/claw bolt |

| 5.8.6 Resistance to disengaging of hook/claw bolt |

| 5.8.7 Resistance to forcing of locating device in sliding door locks |

| 5.8.8 Resistance to pullinf off of knob on bored lock and latch set |

| 5.8.9 Resistance to security reguirements for the locking plate |

| 5.10 Key operation and locking |

| 5.10.1 Strength of key |

| 5.10.2 Deadlocking |

| 5.10.3 Torque to withdraw the latch bolt with key |

| 5.11 Spinder operation |

| 5.11.1 Torque to withdraw the latch bolt with handle |

| 5.11.2 Strength of bolt actions |

| 5.11.3 Minimum follower restoring torque |

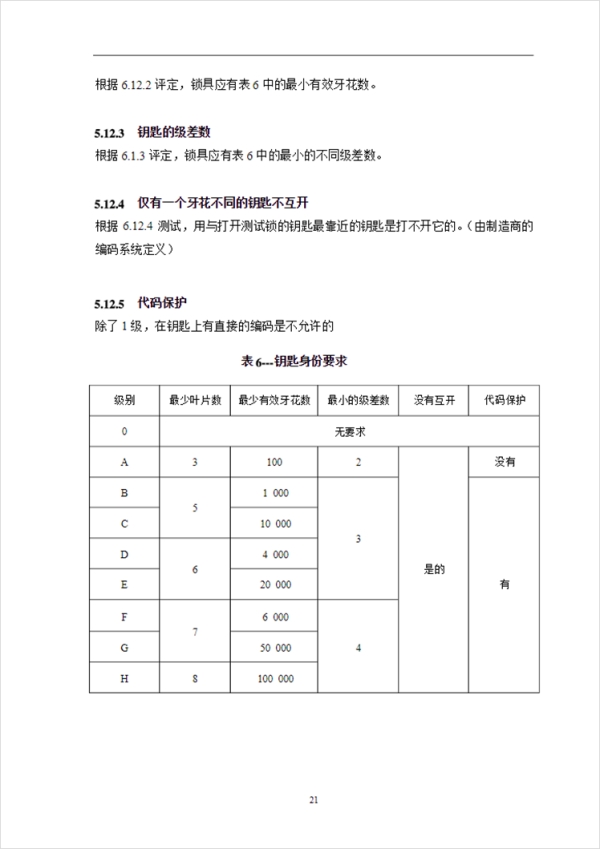

| 5.12 Key identification requirement |

| 5.12.1 Detaining elements |

| 5.12.2 Effective differs |

| 5.12.3 Differing step heights on key |

| 5.12.4 Non-interpassing of keys with just one interval differ |

| 5.12.5 Coding protection |

| 7 Marking |

Annex 各标准测试条款及要求

Annex 1: 级别各位定义

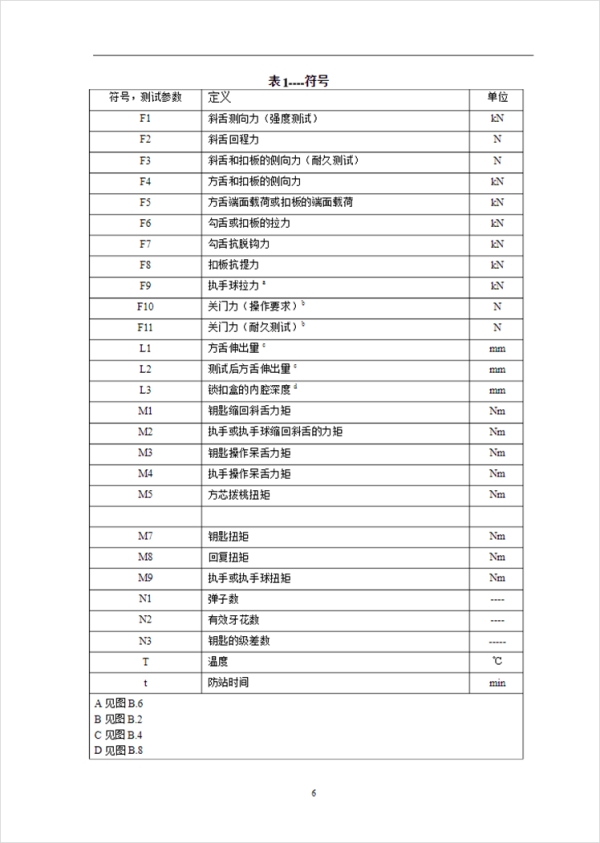

1 | 2 | 3 | 4 | 5 | 6 | 7 | 8 | 9 | 10 | 11 |

Category of use: 使用类别 | Durability 耐用性 | Door mass and closing force: 门重和关门力 | Fire/ Smoke 防火/烟门 | Safety: 安全 | Corrosion resistance 腐蚀 | Security 防盗

| Field of door application 使用场合声明 | Type of key operation and locking 钥匙操作种类 | Type of spindle operation 轴心种类 | Key identification 钥匙级别 |

1, 2, 3 | A, B, C, F, G, H, L, M, R, S, W, X | 1, 2, 3, 4, 5, 6 7, 8, 9 | 0 or 1 | 0 | 0, A, B, C D, E, F, G | 1, 2, 3, 4, 5, 6, 7 | A,B,BC,D,E,F,G,H,J,K,M,N,P,R | 0, A, B, C D, E, F, G, H | 0, 1, 2, 3, 4 | 0, A, B, C D, E, F, G, H |

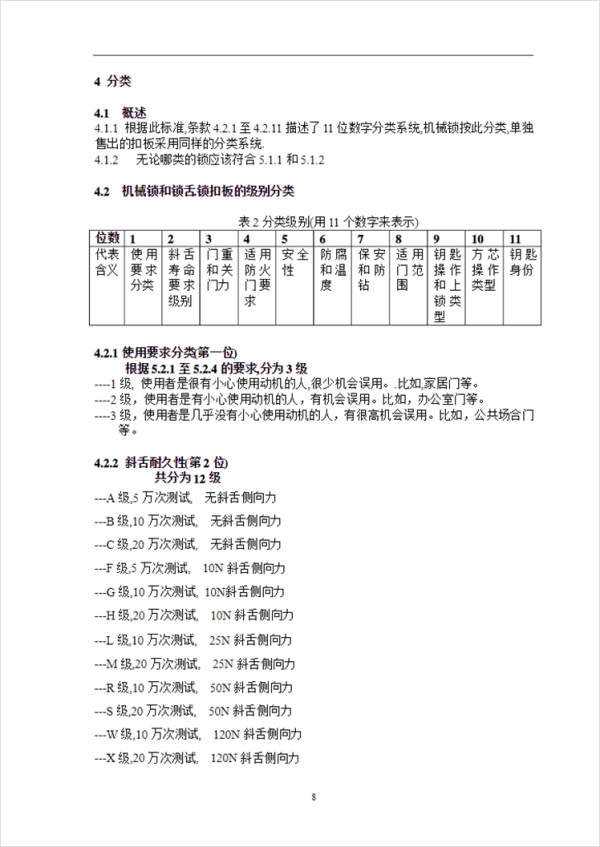

Category of use (first digit)

第一位: 使用类别

Three grades are identified in accordance with requirements stated in 5.2.1 to 5.2.4.

⎯grade 1: for use by people with a high incentive to exercise care and with a small chance of

misuse, e.g. residential doors.

1级: 用在很少有机会被滥用的场合如住宅门

⎯grade 2: for use by people with some incentive to exercise care but where there is some chance

of misuse, e.g. office doors.

2 级:用在会有机会被滥用的场合如办公室

⎯grade 3 : for use by the public where there is little incentive to exercise care and where there is a

high chance of misuse, e.g. doors in public buildings.

3级: 用在经常被滥用的公共场合如公共的建筑物

4.2.2 Durability (second digit)

第二位: 耐用性(循环)

Twelve grades of durability and load on latch bolt are identified.

⎯grade A: 50 000 test cycles; no load on latch bolt;

A 级: 50 000 次循环, 斜舌上不加力

⎯grade B: 100 000 test cycles; no load on latch bolt;

B 级: 100 000 次循环, 斜舌上不加力

⎯grade C: 200 000 test cycles; no load on latch bolt;

C 级: 200 000 次循环, 斜舌上不加力

⎯grade F: 50 000 test cycles; 10 N load on latch bolt;

F 级: 50 000 次循环, 斜舌上加10 N 力

⎯grade G: 100 000 test cycles; 10 N load on latch bolt;

G 级: 100 000 次循环, 斜舌上加10 N 力

⎯grade H: 200 000 test cycles; 10 N load on latch bolt;

H 级: 200 000 次循环, 斜舌上加10 N 力

⎯grade L: 100 000 test cycles; 25 N load on latch bolt;

L 级: 100 000 次循环, 斜舌上加25 N 力

⎯grade M: 200 000 test cycles; 25 N load on latch bolt;

M 级: 200 000 次循环, 斜舌上加25 N 力

⎯grade R: 100 000 test cycles; 50 N load on latch bolt;

R 级: 100 000 次循环, 斜舌上加50 N 力

⎯grade S: 200 000 test cycles; 50 N load on latch bolt;

S 级: 200 000 次循环, 斜舌上加50 N 力

⎯grade W: 100 000 test cycles; 120 N load on latch bolt;

W 级: 100 000 次循环, 斜舌上加120 N 力

⎯grade X: 200 000 test cycles; 120 N load on latch bolt.

X 级: 200 000 次循环, 斜舌上加120 N 力

4.2.3 Door mass and closing force (third digit)

第三位: 门重关门力

Nine grades of door mass and closing force are identified.

⎯grade 1: up to 100 kg door mass; 50 N maximum closing force;

1级: 100 KG门以下, *大关门力: 50 N

⎯grade 2: up to 200 kg door mass; 50 N maximum closing force;

2级: 100 KG到200KG 门重, *大关门力: 50 N

(以下类推)

⎯grade 3: above 200 kg door mass or

specified by the manufacturer; 50 N maximum closing force;

⎯grade 4: up to 100 kg door mass; 25 N maximum closing force;

⎯grade 5: up to 200 kg door mass; 25 N maximum closing force;

⎯grade 6: above 200 kg door mass or

specified by the manufacturer; 25 N maximum closing force;

⎯grade 7: up to 100 kg door mass; 15 N maximum closing force;

⎯grade 8: up to 200 kg door mass; 15 N maximum closing force;

⎯grade 9: above 200 kg door mass or

specified by the manufacturer; 15 N maximum closing force.

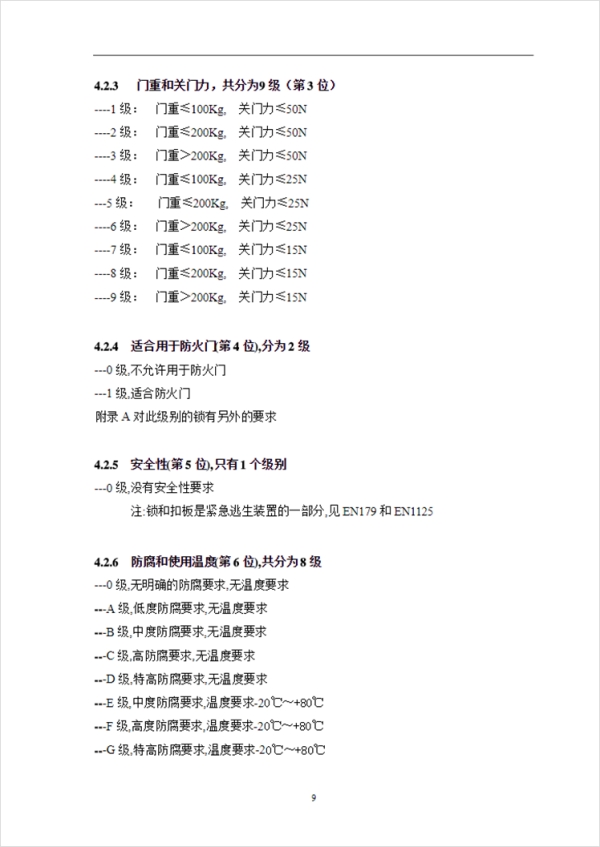

4.2.4 Suitability for use on fire/smoke doors (fourth digit)

第四位: 防火/烟

Two grades of suitability for use on fire/smoke doors are identified.

⎯grade 0: not approved for use on fire/smoke resisting door assemblies;

0级: 不适合用在防火/烟门上

⎯grade 1: suitable for use on fire/smoke resisting door assemblies, subject to satisfactory

assessment of the contribution of the lock or latch to the fire resistance of specified fire/smoke

resisting door assemblies. Such assessment is beyond the scope of this European Standard.

Annex A indicates additional requirements for locks and latches to this grade.

1级: 适合用在防火/烟门上

4.2.5 Safety (fifth digit)

第五位:安全性

only one grade of safety is identified.

⎯grade 0: no safety requirement.

0级: 没有安全的要求

NOTE See EN 179 and EN 1125 for locks, latches and locking plates that are part of exit devices for use on

emergency or panic exit doors.

4.2.6 Corrosion resistance and temperature (sixth digit)

第六位:腐蚀性

Eight grades of corrosion resistance and temperature requirement are identified.

⎯grade 0: no defined corrosion resistance; no temperature requirement;

0级: 没有抗腐蚀的要求,没有温度要求

⎯grade A: low corrosion resistance; no temperature requirement;

A级: 低级抗腐蚀要求,没有温度要求

⎯grade B: moderate corrosion resistance; no temperature requirement;

B级: 中等抗腐蚀要求,没有温度要求

⎯grade C: high corrosion resistance; no temperature requirement;

C级: 高等抗腐蚀要求,没有温度要求

⎯grade D: very high corrosion resistance; no temperature requirement;

D级: 非常高等抗腐蚀要求,没有温度要求

⎯grade E: moderate corrosion resistance; temperature requirement: from –20 °C to +80 °C;

E级: 中等抗腐蚀要求,温度要求–20 °C to +80 °C;

⎯grade F: high corrosion resistance; temperature requirement: from –20 °C to +80 °C;

F级: 高等抗腐蚀要求,温度要求–20 °C to +80 °C

⎯grade G: very high corrosion resistance; temperature requirement: from –20 °C to +80 °C.

G级: 非常高等抗腐蚀要求,温度要求–20 °C to +80 °C

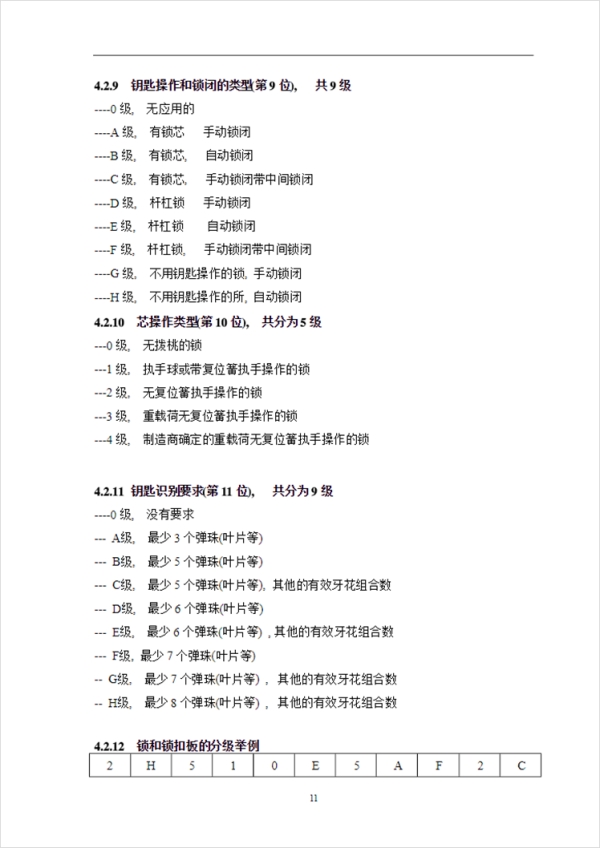

4.2.7 Security and drill resistance (seventh digit)

第七位:防盗防钻

Seven grades of security and drill resistance are identified in Table 5.

⎯grade 1: Minimum security and no drill resistance;

1级: *小防盗性要求,没有防钻要求

⎯grade 2: Low security and no drill resistance;

2级: 低级防盗性没有防钻性要求

⎯grade 3: Medium security and no drill resistance;

3级: 中等防盗性没有防钻性要求

⎯grade 4: High security and no drill resistance;

4级: 高等防盗性没有防钻性要求

⎯grade 5: High security with drill resistance;

5级: 高等防盗性有防钻性要求

⎯grade 6: Very high security and no drill resistance;

6级: 非常高防盗性没有防钻性要求

⎯grade 7: Very high security with drill resistance.

7级: 很高防盗性有防钻性要求

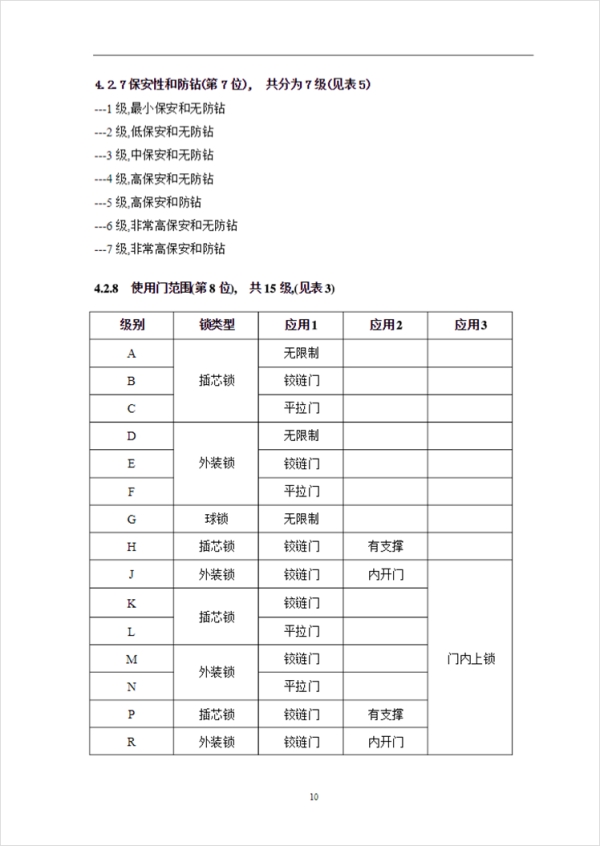

4.2.8 Field of door application (eighth digit)

第8位: 使用场合声明

15 grades of door application are identified in Table 3.

Lead time 测试周期: 常规 Regular service 25 working days

Sample size 送样规格: 15pcs

(1) 15 件自由抽取的样品和它们的原配钥匙(其中两个锁芯每个要带它们*接近牙花的钥匙两把)

(2) 包装,标签和使用说明等信息。

(3) 制造商提供的牙花编排信息,包括牙花数,弹子孔数,弹子级差数

Others 其他信息:

Sample Report 报告样本: