常州FDS-400-BOX腔体喇叭扬声器喇叭发音福鼎

描述

ITEM

SPECIFICATIONS

01

Type

Dynamic speaker

02

Dimension

External diameter40 mm

03

Rated Input Power

2.0W

04

Max. Input Power

2.2W

05

Impedance

4 ohm ± 15% at 1500Hz.

06

Resonance Frequency (Fo)

500Hz ± 20% at Fo, 1V

07

Sensitivity (S.P.L.)

103dB(1.0W/0.1m) ± 3 dB

at AVE0.6K,0.8K,1.0K,1.5KHz.

08

Frequency Range

Fo –20KHz

09

Total HarmonicsDistortion

Max 8 % at 1 KHz,2.2W.

10

Voice Coil

Diameter 16.3 mm

11

Magnet

Rare earth permanent (Nd-Fe-B) magnet Φ15.0 x3.0 mm

12

Weight

25.5g ± 0.2g

13

Appearance

Should not exist any obstacle to be harmful to normal operation; damages, cracks, rusts and distortions, etc.

14

Operation Test

Must be normal at program source – 2.0W

15

Buzz, Rattle, etc.

Should not be audible at2.83V sine Wave between Fo to 20KHz

16

Polarity

When positive voltage is applied to the terminal marked (+), diaphragm should move to the front.

17

Terminal Strength

Capable of withstand 1kg load for 30 seconds without resulting in any damage or rejection.

18

Temperature

Operating temperature: -20℃ to +60℃

Storage temperature: -30℃ to +70℃

Test Condition

STANDARD

Temperature :15 ~ 35℃

Relative humidity :25% ~ 85%,

Atmospheric pressure : 860mbar to 1060mbar.

BASIC

Temperature : 20±3℃

Relative humidity : 60% ~ 70%,

Atmospheric pressure : 860mbar to 1060mbar

Standard Test Fixture

1.Input Power :1.0W( 2.0V )

2.Zero Level : -dB

3.Mode : SPEAKER

4.potentiometer Range : 50dB

5.Sweep Time : 0.5sec

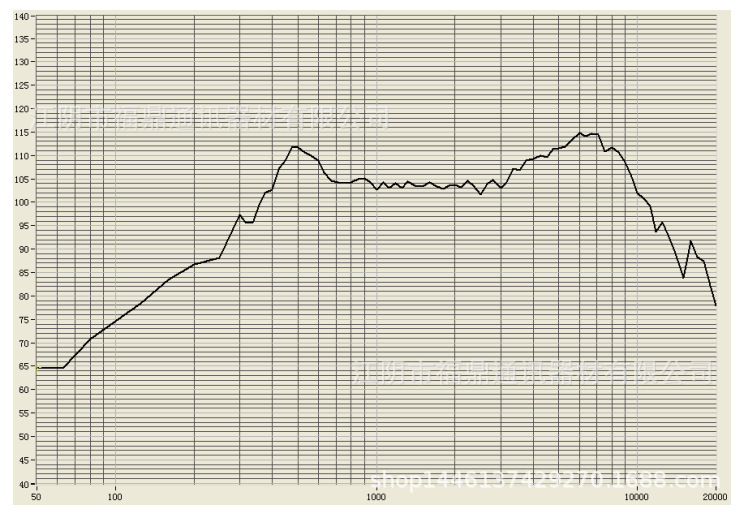

Frequency Response Curve

RELIABLITY TESTS

Items.

Specifications

01

High temp. Test

Keep 96 hours at +70℃±3℃ and leave 3 hours in normal temperature and then check

02

Low temp. Test

Keep 96 hours at -30℃±3℃ and leave 3 hours in normal temperature and then check

03

Humidity test

Keep 96 hours at + 60℃±3℃ relative humidity 95% and leave 3 hours in normal temperature and then checked.

04

Temp./Humidity cycle

The part shall be subjected5 cycles. One cycle shall be12 hours and consist of;

05

Thermal cycle test.

Low temperature: -30℃±3℃,temperature:+70℃±3℃,cycle:

1hour/cycle each, and then keep5 cycles in a room.

06

Vibration

10~200~10Hz sin-wave sweep 15min.5G(constant)

X,Y, Z 3 direction.2 hours each, total 6 hours.

07

Fix drop test

Fix on jig. Then drop from 152cm height to the concrete floor

X, y, z 6 direction. 5 times each, total 30 times.

08

Free drop test

Free drop from 100cm height to the concrete floor

X, y, z 6 direction.1 times each, total6 times.

09

Rated Power test

Rated Powerwhite noise is applied for 96 hours

10

MaxPower test

Max power 1 min on– 2 min off 10 cycles.

11

Terminal strength test

Capable of withstand 1kg load for 30 seconds without resulting in any damage or rejection.

Criterion:

After these test , the change ofS.P.L shall be within±3 dB .

SOLDERING CONDITION

Recommend using constant branding iron in15 ~ 30W, and in temperature range350°C.

Soldering time not over 3 seconds.